In-vacuum selective and standard metallization

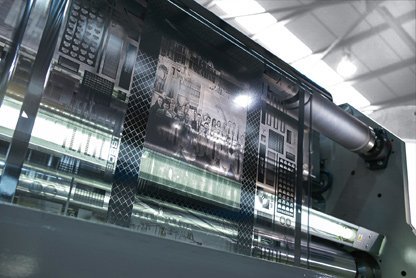

T he new Bobst SelectMet system incorporates Bobst F&Yard heritage flexo press technology into a Bobst vacuum metallizer and is a simpler and more cost-effective alternative to the traditional de-metallization process without the complexity of special lacquers and chemical bath

Selective and standard metallization from ane machine

The innovative Bobst SelectMet process runs at speeds of up to 400 metres a minute on the Bobst K4000 platform. This provides greater flexibility as ane car can be used for two processes, both standard aluminium metallization and selective metallization without compromise. SelectMet is simply available in the most commonly used metallizer widths in the converting industry – 1,250 mm and i,650 mm.

Flexo printing unit within the vacuum bedchamber

The flexo printing unit is located inside the vacuum sleeping room and the printhead position tin be moved accordingly depending on which process is to be run; for selective metallization the printhead moves towards the blanket pulsate and so retracts dorsum to a dwelling position (abroad from the picture web path) for standard metallization.

Minimum oil consumption

This in-line vacuum metallizing process consists of a special printing oil which is applied at room temperature to the spider web in a very thin layer to produce the desired pattern. The low volume anilox cells ensure minimum oil consumption (downwards to less than 0.five grams a foursquare metre). The polished anilox roller combined with a high precision doctor blade made out of carbon fibre allows more efficient and accurate oil metering.

Unlike the traditional and rather messy oil boilers, in the unique Bobst SelectMet system the oil is loaded at room temperature through an external oil bathroom. This results in a much cleaner selective metallization procedure. The location of the oil bath outside the vacuum sleeping room means that additional oil tin can exist added during production to salve fourth dimension and enable longer runs.

Quick and easy sleeve change

Another key feature of the new Bobst SelectMet is the quick and easy change of the printing sleeve. The printing unit of measurement retracts and aligns itself with the viewing port located on the side of the machine which gives like shooting fish in a barrel access to the printing roller though the porthole window. The printing sleeve itself is a one slice cylindrical polymer sleeve which tin can be easily loaded with the assist of an air flotation bed. The quick release bearing house allows sleeve changeover in less than 10 minutes. SelectMet incorporates an interchangeable bridge adaptor which allows the use of different diameter printing sleeves. Click here to see the Bobst SelectMet video.

Faster, more than accurate printing for a diverseness of applications

Bobst'due south SelectMet provides faster, more accurate printing with metal onto film substrates and allows for the production of creative, high resolution patterns and greyscale images. A flexible and versatile oil printing process organization; SelectMet provides a wide range of added-value applications for specialist converters such every bit:

Innovative decorative packaging films – production of cutting-edge decorative films which tin can be used for centre-catching packaging to attract consumers' attending Stripe metallization – leaves a window of un-metallized flick that allows product visibility and evokes desire towards impulse purchases In-Register selective metallization onto pre-printed webs – pre-printed pic is used as a base of operations resulting in circuitous patterns incorporating both colored and metallized areas Anti-counterfeiting applications – production of high resolution selective metallization used in security threads and holographic foils that offering protection against counterfeiting in banknotes and other security applications.

Also available is an optional ZnS source for production of decorative holographic films with enhanced effulgence to reduce fake and provide loftier make recognition for security and protection applications.

Packaging South Asia is the cooperating media partner for drupa 2022 which is scheduled to exist held from 31 May to 10 June at Dusseldorf, Germany.

Source: https://packagingsouthasia.com/events/in-vacuum-selective-and-standard-metallization/

0 Response to "In-vacuum selective and standard metallization"

Publicar un comentario